Operations Environmental Management(Green Building) | Workplace Environment | Happiness Workplace | ASUS ESG website, ASUS ESG goal

ASUS adheres to the business philosophy of "striving to be among the world-class green high-tech leaders". We believe that we should take care of the environment in exchange for the nature resources that bring profits to us. We incorporate environmental considerations into our operational decision making process, continue to develop products with low environmental impact, and establish a dedicated team that ensures ASUS complies to all relevant environmental regulations by assessing corporate activities. ASUS will continue to formulate and implement action plans to minimize the impact on the environment and continue to move towards the goal of "zero pollution".

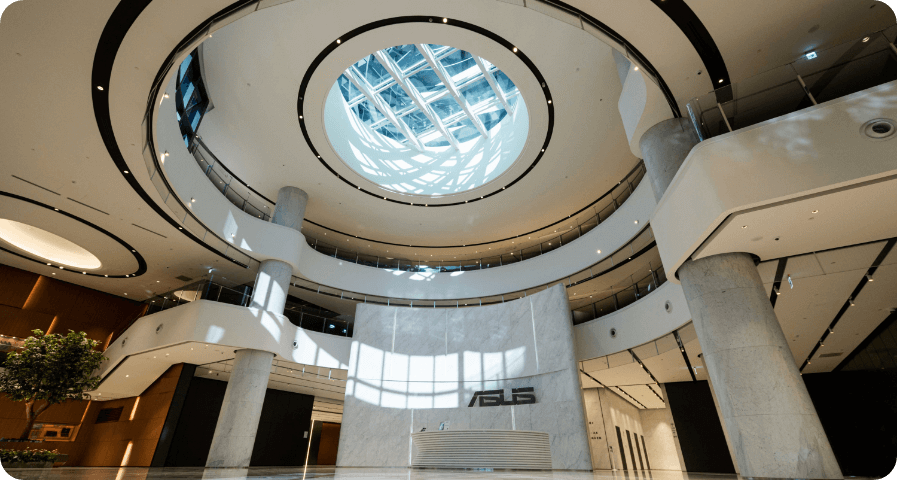

When selecting the location of the headquarter, we decided to locate in a legal science and technology park. The establishment of this area is subject to strict environmental impact assessment. It is not only outside the scope of the nature reserve but also considers factors such as the preservation of biodiversity, ecosystems and natural species, and no deforestation to avoid any negative impacts. At the same time, we implement management based on the following major environmental issues to reduce the environmental footprint of our operations.